48% Cost Savings

CASE STUDY – LED INDUSTRY

The Need

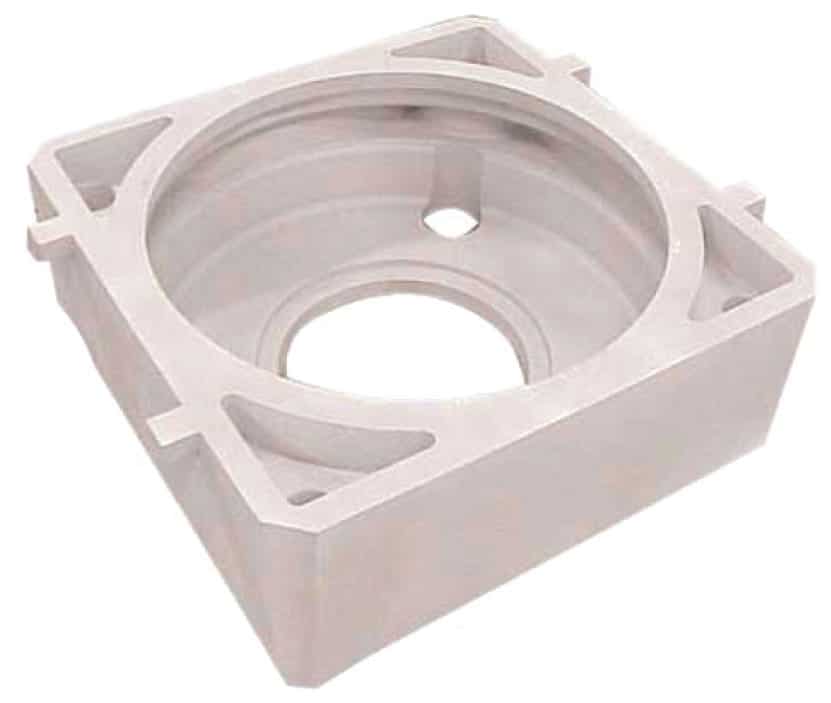

This company did not know that casting could be used to create vacuum chambers. They were using a “hogged out” process from a block of aluminum with significant machining.

The Solution

By applying our VaPore® aluminum casting technology to create these vacuum cast chambers, we achieved a 48% per part savings. In this case the pattern paid for itself after 4.6 units. This translated into a nearly $2 million in material cost savings in just the first two years of production.

Machined Billet vs. Palmer VaPore Casting

Machined Billet

Raw Material:

$4,300

Machining:

$2,500

Total:

$6,800

Pattern NRE:

$14,300

Raw Material:

$2,569

Machining:

$1,000

Total:

$3,569

Per Part Savings: $3,231 (or 48%) Pattern pays for itself after 4.6 units