Engineering

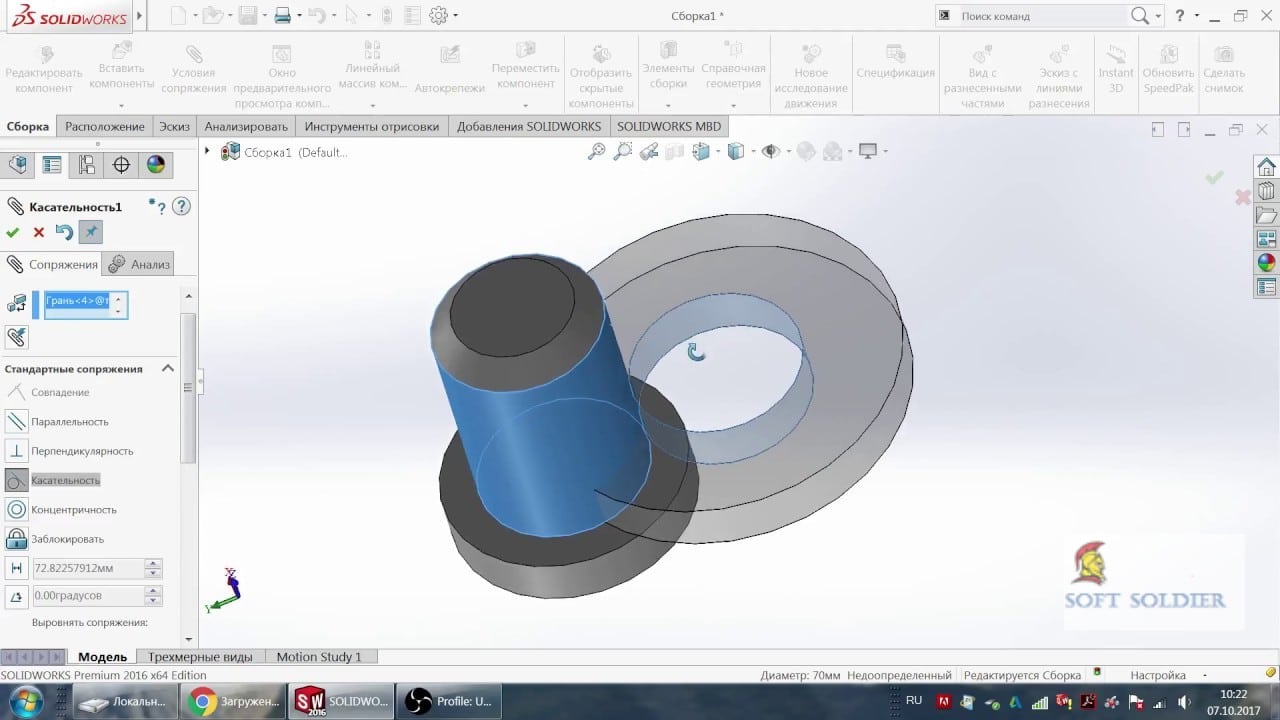

SOLIDWORKS Premium streamlines the Product Development Process

SOLIDWORKS Premium’s integrated 3D CAD technologies helps Palmer Foundry develop better products and bring them to market faster.

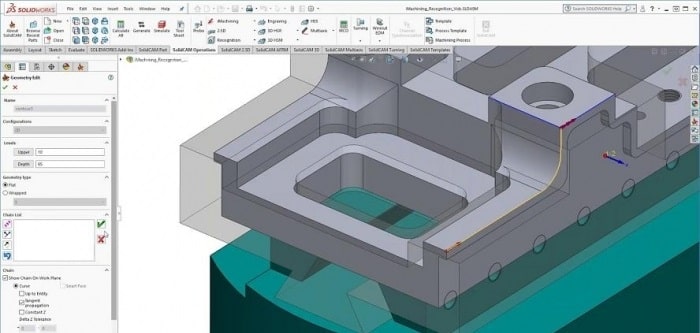

SOLIDWORKS Premium allows Palmer Foundry’s high skilled engineers to perform virtual product simulation, design validation, CNC tool path generation, tooling development, and documentation development. Leading to a more efficient and accurate cost and quote for our customer’s product

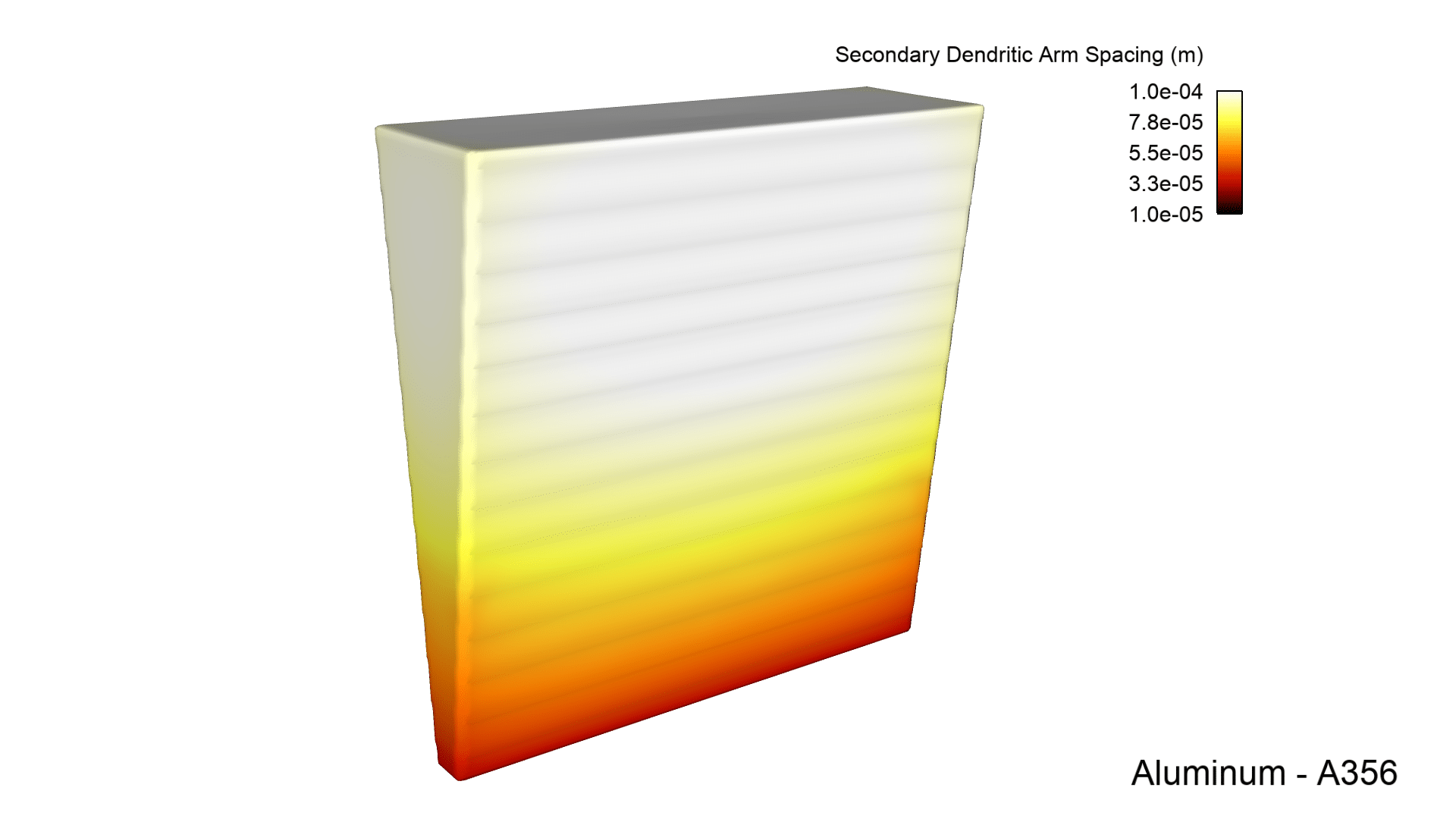

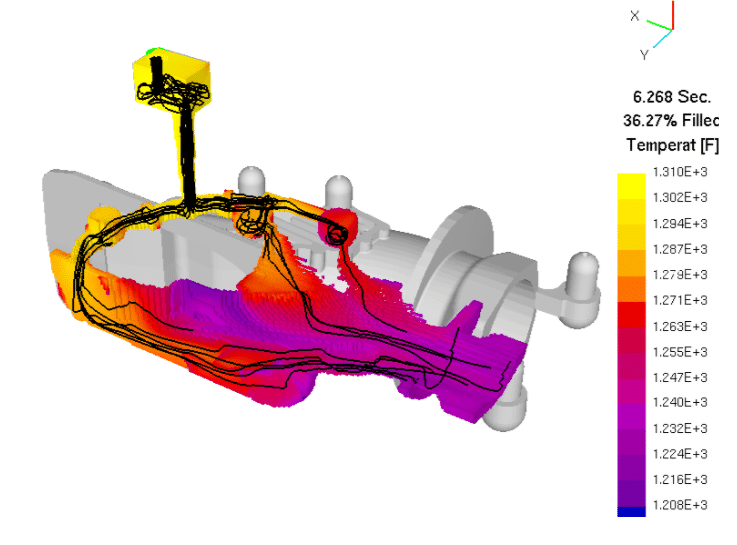

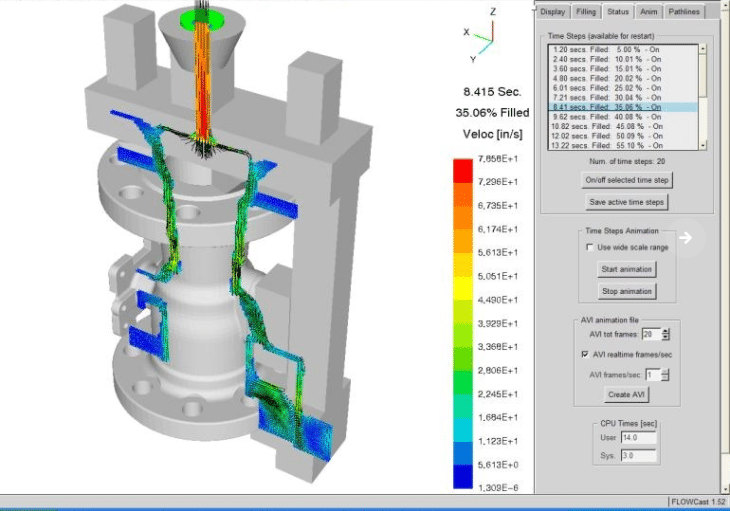

FLOWCast allows us to model convection, conduction and radiation within the mold cavity. This allows Palmer Foundry to analyze casting and gating design to predict and minimize flow-related defects such as mis-runs due to premature solidification, oxide formation, or mold erosion to excessive velocities during filling.